Challenge

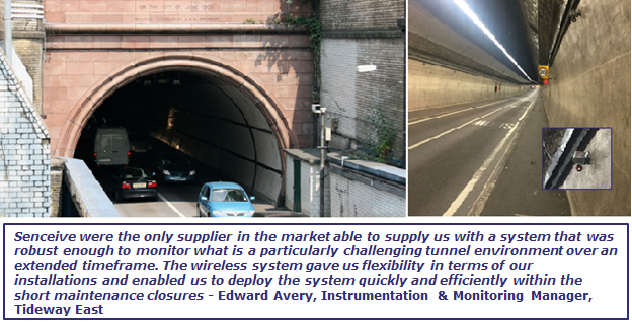

The Thames Tideway Tunnel will provide capture, storage and movement of almost all the sewage and rainwater discharges that currently overflow into the river Thames from central London. The Rotherhithe Tunnel sits in close proximity to the Tideway East shaft site.

CVB (Costain, VINCI Construction Grands Projets and Bachy Soletanche), along with Sixense as their appointed monitoring contractor, required a monitoring system 12 months ahead of impacting works, to provide a sufficient period of baseline monitoring and continuing until any movements associated with the works have ceased.

Access was only allowed during night-time engineering closures that took take place once per week. Another challenge was that the majority of the tunnel lining is tiled and is very delicate and as such, TfL were reluctant to allow fixings into it. Every two weeks a machine, which combines a spinning brush and high pressure hot water jet, runs through the tunnel in order to clean this tunnel lining. Therefore, any system had to be robust enough to survive the twice monthly tunnel cleaning.

Solution

Senceive provided their wireless FlatMesh™ system as a monitoring solution. 74 high precision tilt sensor nodes were installed by Sixense during engineering closures over an 8 week period to monitor any convergence/ divergence during the works.

64 of the nodes were installed directly onto the tunnel lining in 16 arrays of 4 nodes per array. A further 10 nodes were mounted on 3m beams in a vertical shaft. The FlatMesh™ system allowed all the nodes to communicate with each other and measure sub-mm movements for an estimated project duration of 3-5 years.

The data is received by two wall-mounted 3G gateways, positioned and powered at the base and top access chamber of Shaft 3 with the data being relayed and transmitted via an antenna at the top of this shaft. This secure data was then easily sent through the mobile GSM network and accessed by registered users of the Senceive WebMonitor data visualisation software and the client’s own software. The nodes could also be remotely configured to provide near real-time data frequency if required.

Solution

Senceive provided their wireless FlatMesh™ system as a monitoring solution. 74 high precision tilt sensor nodes were installed by Sixense during engineering closures over an 8 week period to monitor any convergence/ divergence during the works.

64 of the nodes were installed directly onto the tunnel lining in 16 arrays of 4 nodes per array. A further 10 nodes were mounted on 3m beams in a vertical shaft. The FlatMesh™ system allowed all the nodes to communicate with each other and measure sub-mm movements for an estimated project duration of 3-5 years.

The data is received by two wall-mounted 3G gateways, positioned and powered at the base and top access chamber of Shaft 3 with the data being relayed and transmitted via an antenna at the top of this shaft. This secure data was then easily sent through the mobile GSM network and accessed by registered users of the Senceive WebMonitor data visualisation software and the client’s own software. The nodes could also be remotely configured to provide near real-time data frequency if required.